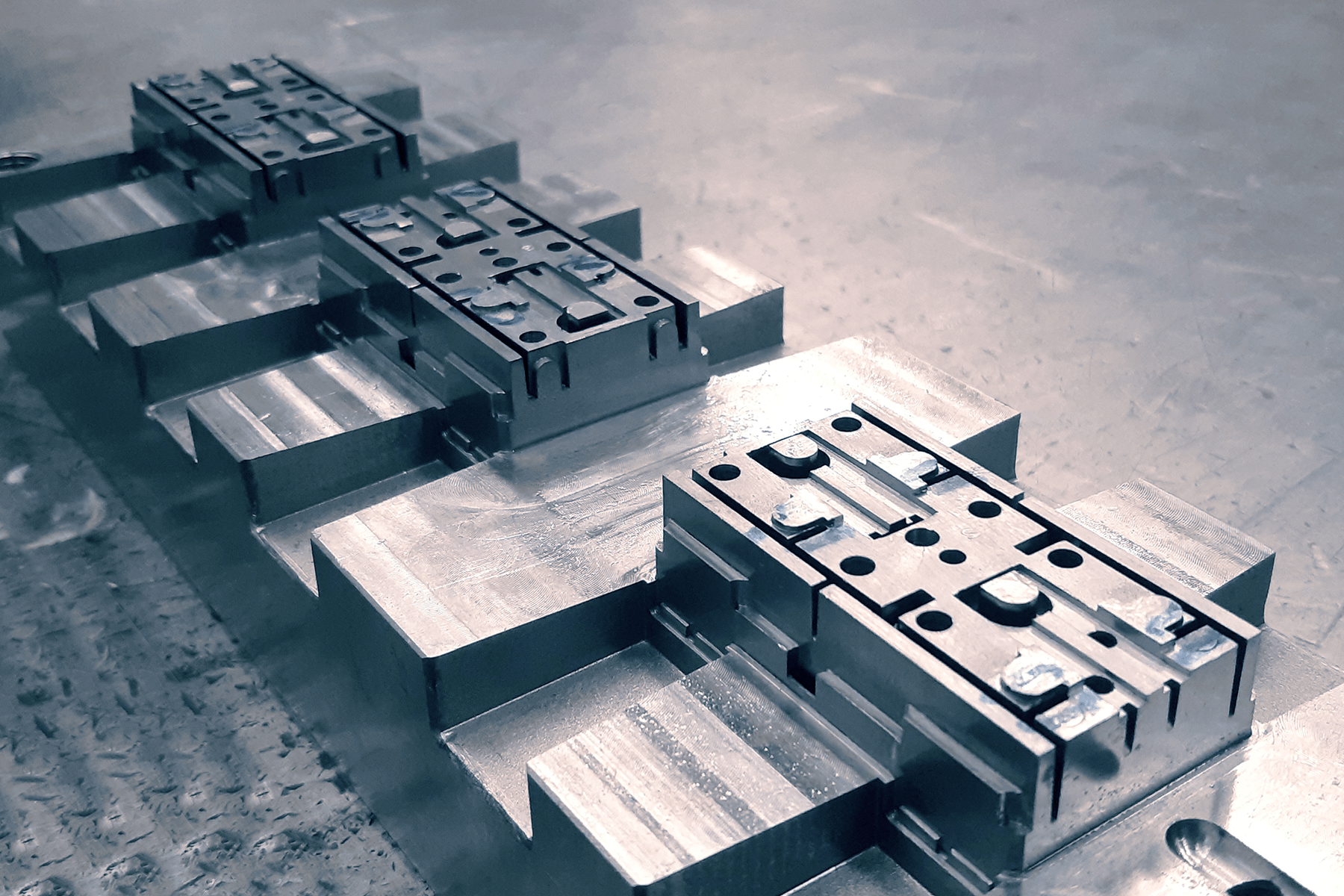

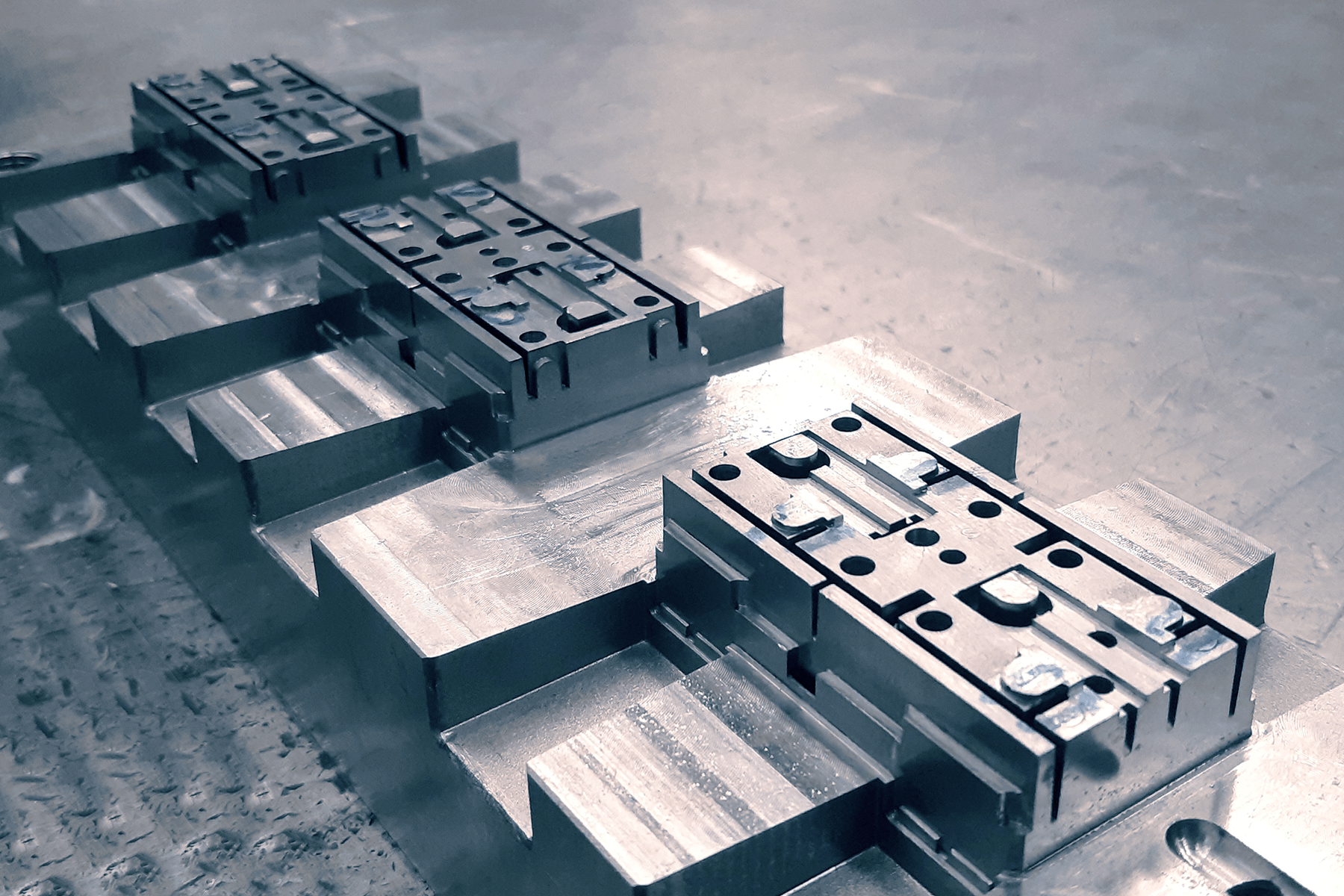

Our subsidiary Matotech is specialized in:

- Stamping and forming tools

- Injection moulding tools

- Jigs and fixtures

- Development and design

- Maintenance and repair

More information about Matotech can be found HERE

Industrial services from a single source as well as the holistic support of projects are more and more requested in the industrial world. We can support you based on your individual needs. Together we define the best service package for you, either a full “hands-free” service (supervising and handling projects as a general contractor) or Seifert is taking care of individual requirements.

Our subsidiary Matotech is specialized in:

More information about Matotech can be found HERE

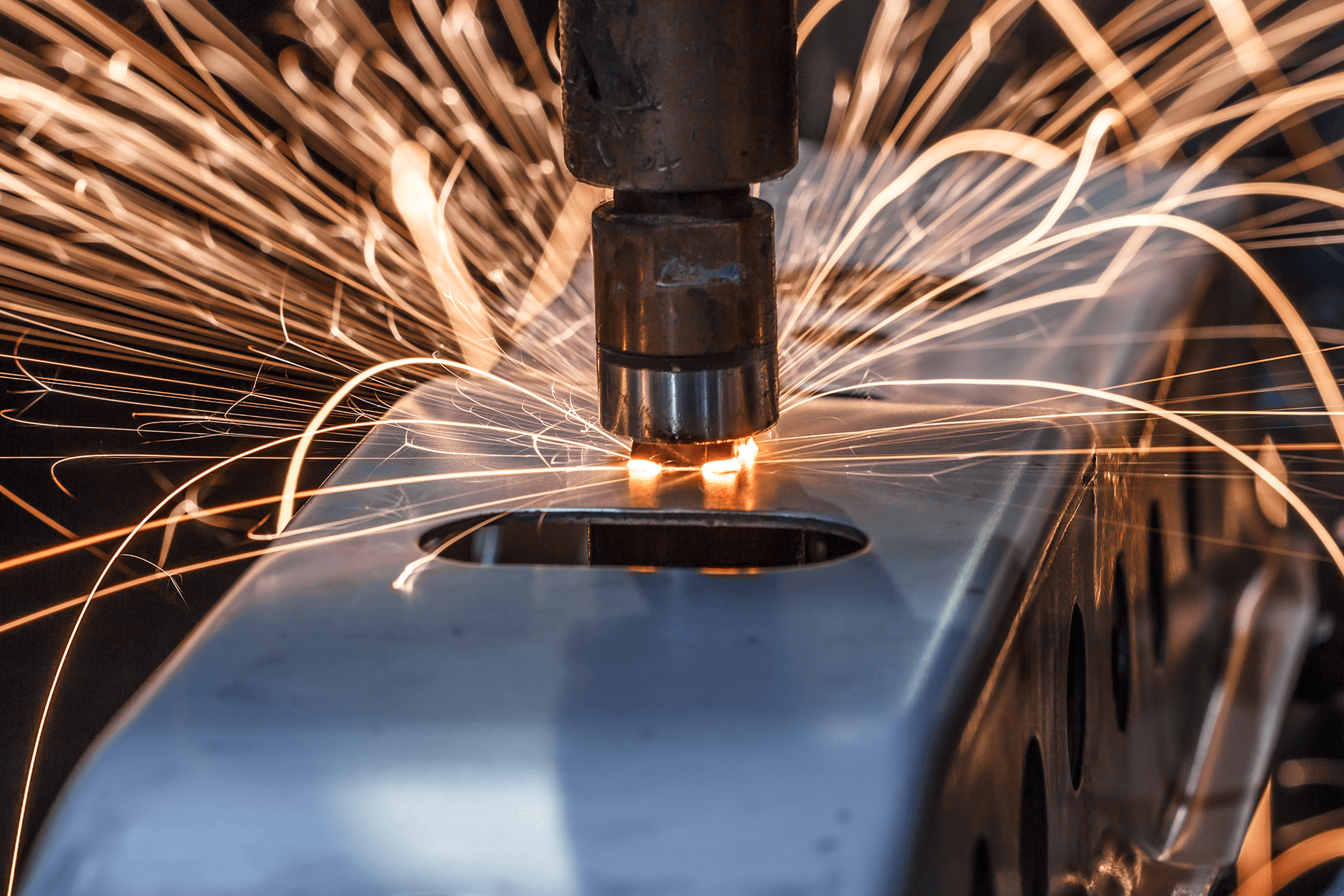

We offer the full range of processes for metalworks:

We process aluminum, stainless steel, mild steel, structural steel and copper. Other materials can also be offered on request.

We offer surface finishing. Based on the requirements we clean, sand, brush or satin the surfaces. Our specialists grind and polish your metal parts after welding in order to achieve a visually perfect surface.

Our surface treatment services include:

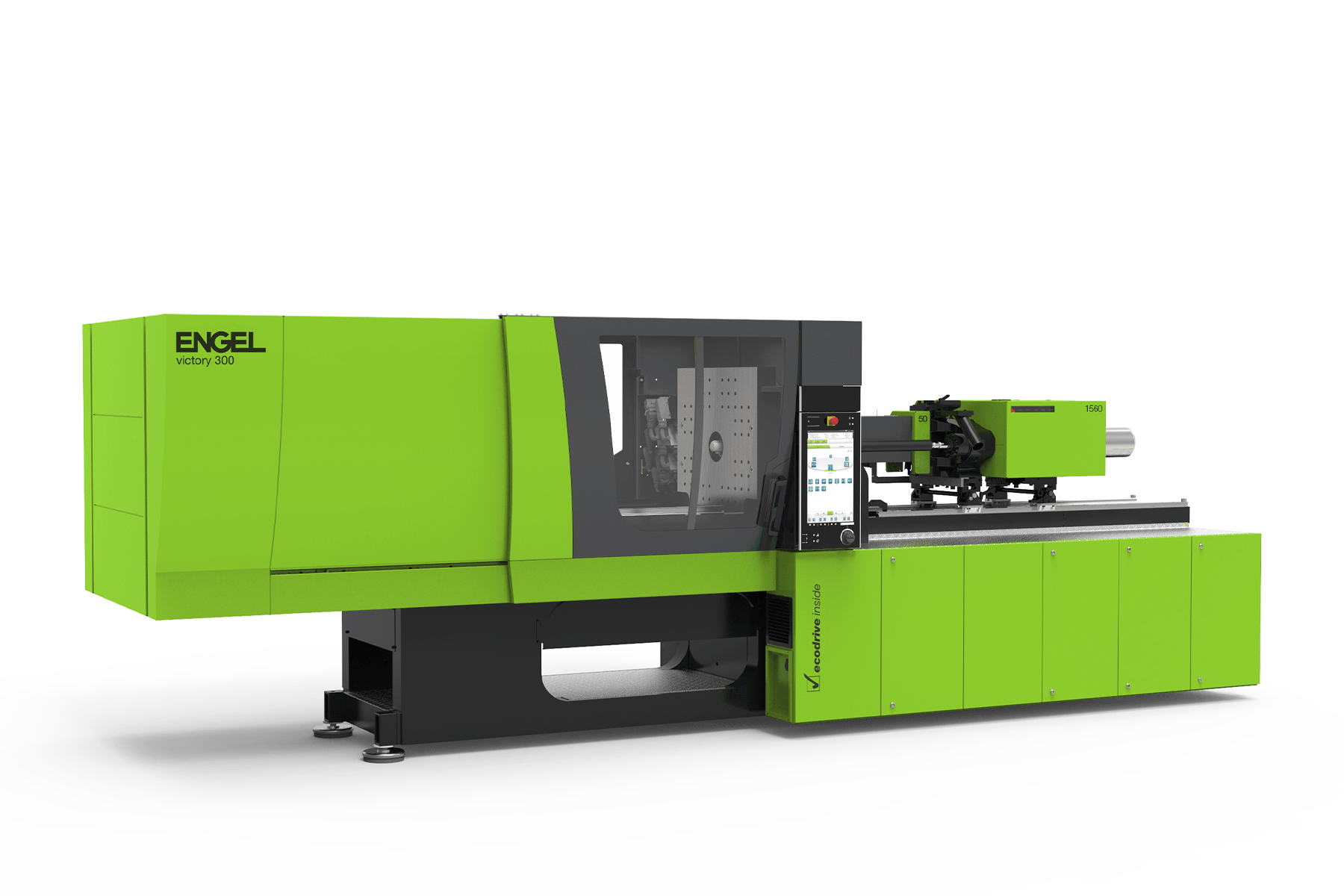

Many years of experience in the field of injection molding of technical plastic parts allows us to be at your side as a competent partner from the planning to the production of your injection molded parts. We can either take over existing tools or offer and implement new projects completely.

We process technical thermoplastics through to high-performance plastics. Our injection molding machines have a clamping force of up to 300 tons.

Our services include

Accroding to your requirements our state-of-the-art cable assembly facility offers different work steps at the highest quality level.

Our services include:

With our One-Stop-Shop we manufacture complete assemblies, select suppliers, purchase, dispose and store components as well as doing the entire logistics for you, thus streamlining your supply chain and optimizing your costs.

| Your advantages | Our services | |

|---|---|---|

• Inexpensive purchase of ready to use assemblies | • Plastic and mechanical assemblies | |

• No procurement and logistics costs | • Ultrasonic welding, heat staking | |

• No quality risk | • Pad and screen printing | |

• Shortening of the supply chains | • ESD protected environment | |

• Warehousing of finished components | • Logistics, customer specific distribution |

Seifert stands for innovative products, the highest quality and efficient processes. Our quality assurance always focuses on the requirements of our customers.

You learn from mistakes – based on our philosophy of open and transparent communication we believe every mistake also means the chance to develop further. That is why our quality assurance already takes place in the individual production processes. By carrying out internal and external audits, we strengthen the quality awareness of each individual employee.

Of course, our quality management complies with the requirements of DIN EN ISO 9001: 2015

Questo include cookie necessari per il funzionamento del sito, così come altri utilizzati solo per scopi statistici anonimi o per la visualizzazione di contenuti esterni. Puoi decidere autonomamente quali categorie desideri consentire. A seconda delle tue impostazioni, potrebbe non essere possibile utilizzare tutte le funzionalità del sito. I dettagli sono disponibili nella nostra Politica sulla riservatezza.

Questo include cookie necessari per il funzionamento del sito, così come altri utilizzati solo per scopi statistici anonimi o per la visualizzazione di contenuti esterni. Puoi decidere autonomamente quali categorie desideri consentire. A seconda delle tue impostazioni, potrebbe non essere possibile utilizzare tutte le funzionalità del sito. I dettagli sono disponibili nella nostra Politica sulla riservatezza.

Per visualizzare questo elemento, è necessario il consenso all'uso dei cookie nella seguente categoria: {category}.